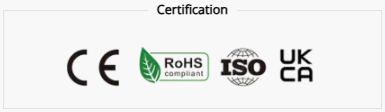

16×24 Pneumatic Up Sliding Dual Platen Heat Press Machine With Infrared Positioning

| Voltage(V): | 110V/60HZ |

| Power(KW): | 2 |

| Temperature(℃): | 0-299 |

| Delaying time(S): | 1-999 |

| G.W.(LB): | 306.5 |

| Packing Size(in): | 42.5” x 33.9” x 32.3” |

| Accept Thickness: | Max. 2.36” Thick Items |

| Range of Application: | Pure Cotton, Polyester, Chemical Fiber, Pearl Board, Metal Pendant, Mousepad, Vitrolite, Ceramics |

| Heat Plate Size: | 16” x 24” (40 x 60cm) |

Features

- Heat press machine is full digital integrated display control;

- High accuracy of signal indication when press process is completed;

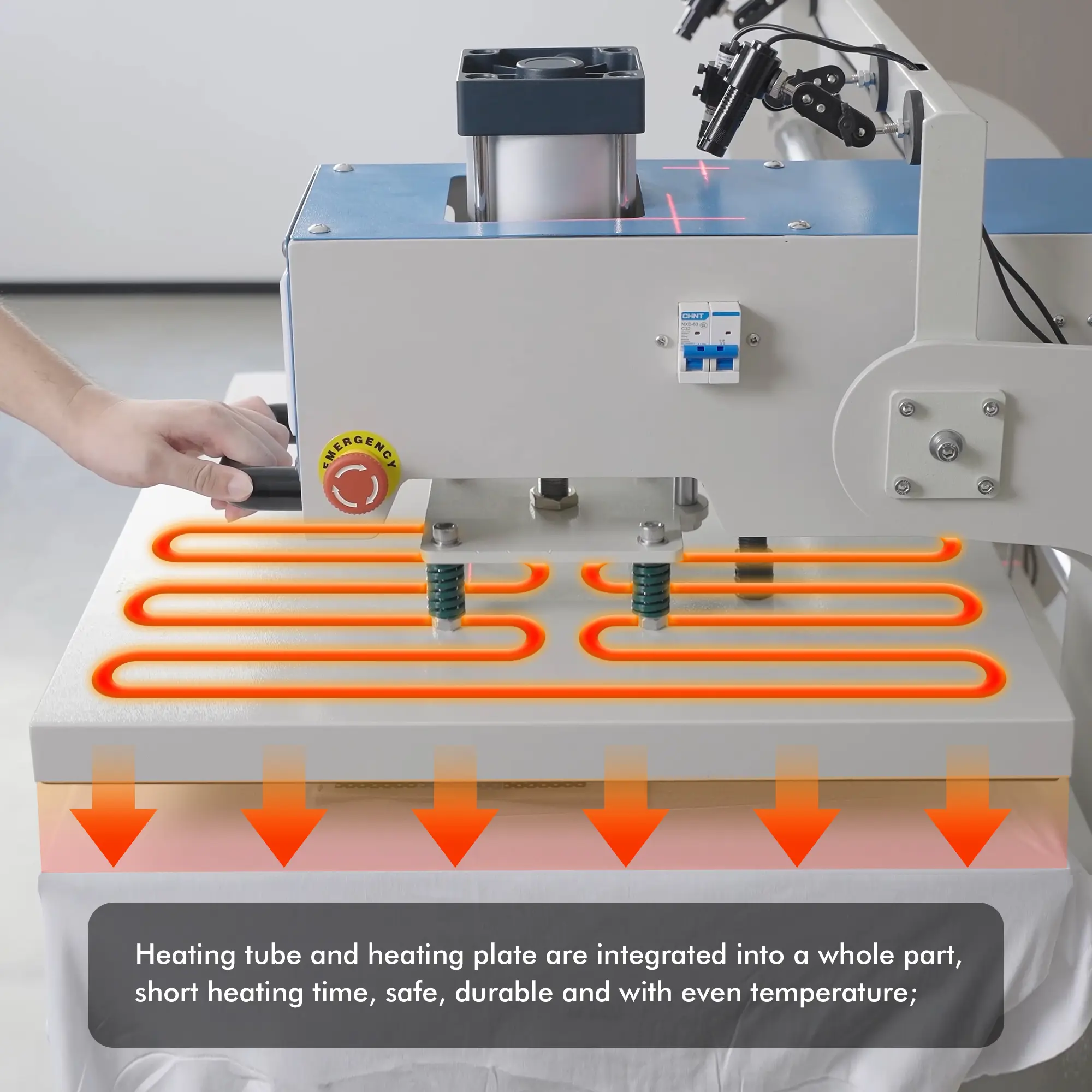

- Heating tube and heating plate are integrated into a whole part, short heating time, safe, durable and with even temperature;

- Heat press machine pressure can be adjusted up to 10 bar, It adopts connected track which is stable and convenient for sliding, with high efficiency;

- Special high temperature cloth for hot stamping machine covered

- Lower plate covered with silicon mat and sponge to heat even heating pressure

- Heat press machine is automation print once backside inductive screw touched

- Left and right side bearings parallelly move the heat press machine

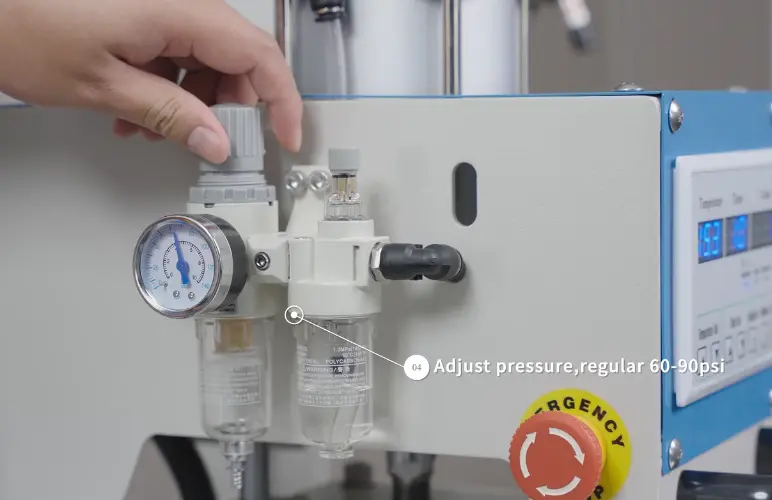

- General pressure for 0.4Mpa-0.6Mpa heat printing

Time and Temperature Requirements of Different Materials

| Material | Time | Temperature |

| Pure cotton | 15s-25s | 356℉-428℉ (180℃-220℃) |

| Polyester | 40s | 356℉ (180℃) |

| Chemical fiber | 10s-40s | 302℉-356℉ (150℃-180℃) |

| Pearl board | 60s-100s | 356℉ (180℃) |

| Metal pendant | 60s | 356℉ (180℃) |

| Mousepad | 50s | 374℉ (190℃) |

| Vitrolite | 180s | 392℉ (200℃) |

| Ceramics | 180s | 356℉-428℉ (180℃-220℃) |

Dual Platen Efficiencys

Each platen operates independently, allowing for continuous printing; while one item is being pressed, the other can be set up, effectively doubling your productivity.

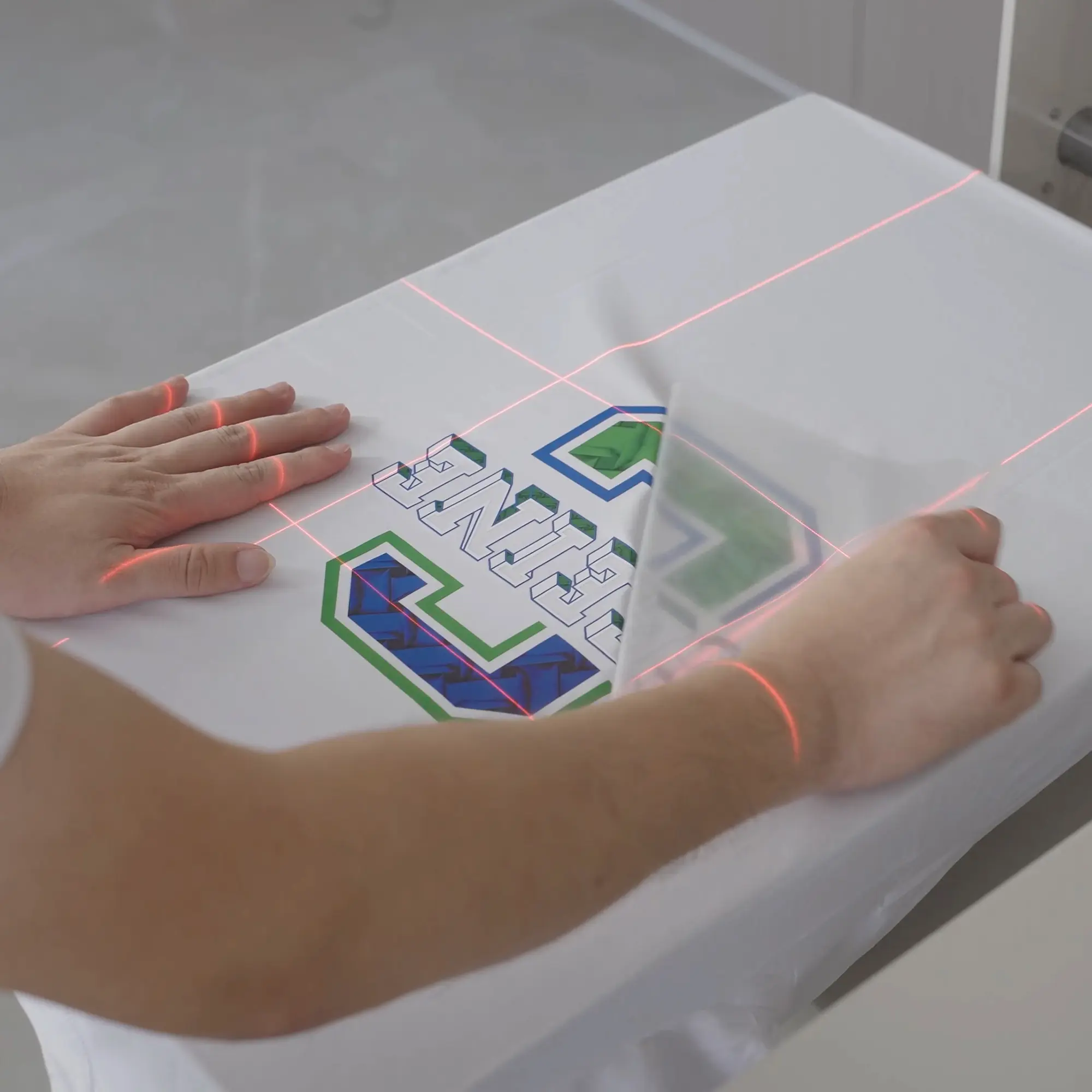

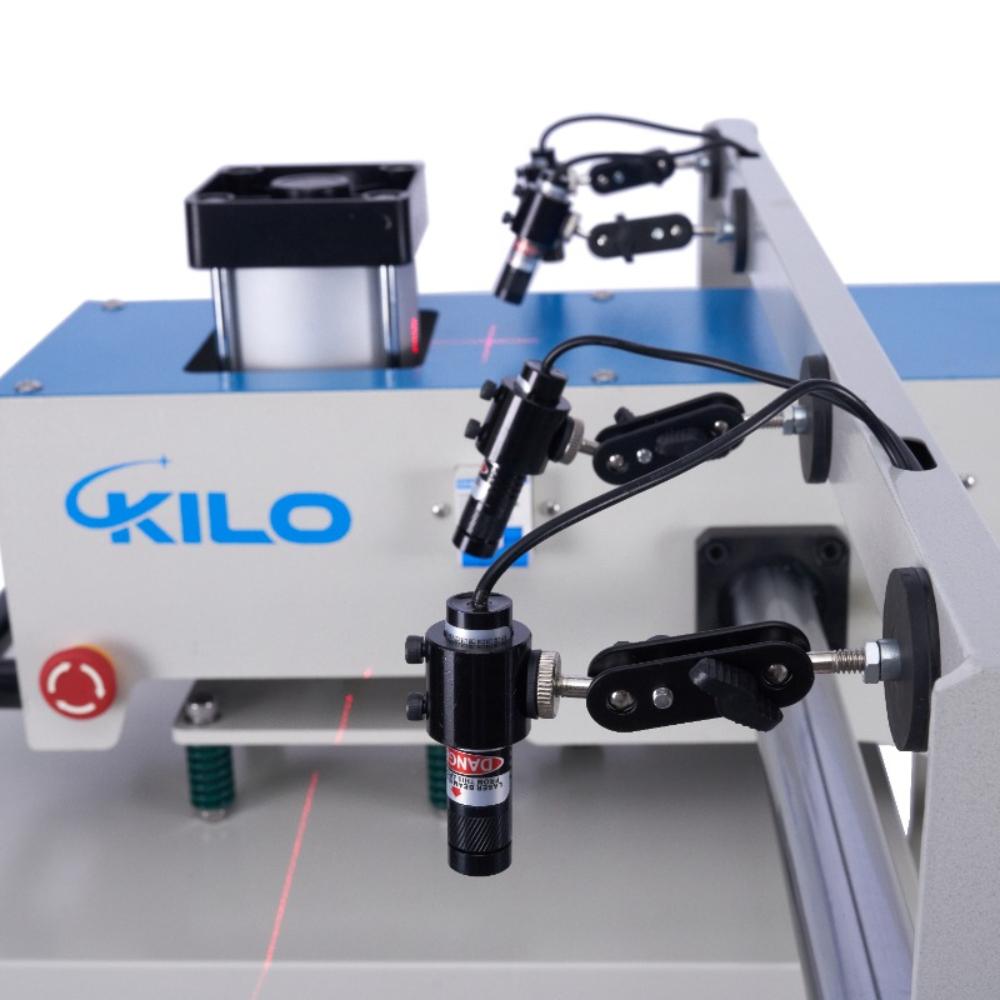

Laser positioning

This Dual Platen heat press stands out with its infrared positioning, a sophisticated feature rarely found in compact models.

This system ensures precise placement of transfers.

Pneumatic Pressure System

The pneumatic pressure system delivers consistent, This feature ensures high-quality, uniform transfers on a variety of materials.

Programmable Digital Control

You can program and monitor temperature, pressure, and timing with precision, making complex printing tasks simpler and more reliable.

FAQs

-

Can this heat press improve production efficiency?

Yes. Our up sliding dual platen heat press machine allows you to prepare one product at the same time as pressing another, making stamping easier and more precise, which means it reduces production time and increases throughput.

-

Is this 16X24 heat press machine competent for complex printing tasks?

Yes. Our heat press pressure can be adjusted up to 0.8Mpa, higher accuracy of signal indication when press process is completed compared to 0.4Mpa-0.6Mpa heat press in the market. Widely used in cotton, polyester, chemical fiber, bead board.

-

What should I do if I can’t understand installation or operation instructions?

We will arrange a professional technician to call and guide you, and send a video or picture of the operation.

-

What is this heat press being transported through?

Our heat press is large product that requires specialized transportation by truck. In addition, was packaged in a nice wooden crate.

Reviews

Clear filtersThere are no reviews yet.